Introduction to Product Design Services

Product design services encompass a wide range of activities that transform initial ideas into tangible, market-ready products. The process begins with conceptualization, where designers and engineers collaborate to understand the client’s vision and establish the parameters for the project. This structured approach is essential for ensuring that every detail is meticulously crafted, from functionality to aesthetic appeal. The emphasis on innovation is crucial in a competitive market, as it helps to differentiate products and fulfill consumer demands effectively.

These design services cater to a diverse clientele, including startups, established businesses, and individual inventors. Startups, in particular, benefit from a guided approach, as they often have limited resources and need to optimize their design processes for efficiency. By leveraging product design services, startups can access expertise that helps them navigate the complexities of product development, ensuring that their concepts evolve into successful finished products. Similarly, inventors can gain vital support, turning their unique ideas into commercial realities with professional design input.

In addition to fostering creativity, product design services emphasize the importance of practicality and usability. This dual focus allows designers to create products that are not only visually appealing but also functional and user-friendly. Staying attuned to market trends and consumer preferences, design services benefit from incorporating the latest technologies and materials, which can significantly enhance product potential. Ultimately, the effectiveness of product design services lies in their ability to marry innovation with practicality, enabling clients to bring their visions to life seamlessly, from conception through to the final product.

Guiding You Through the Design Process

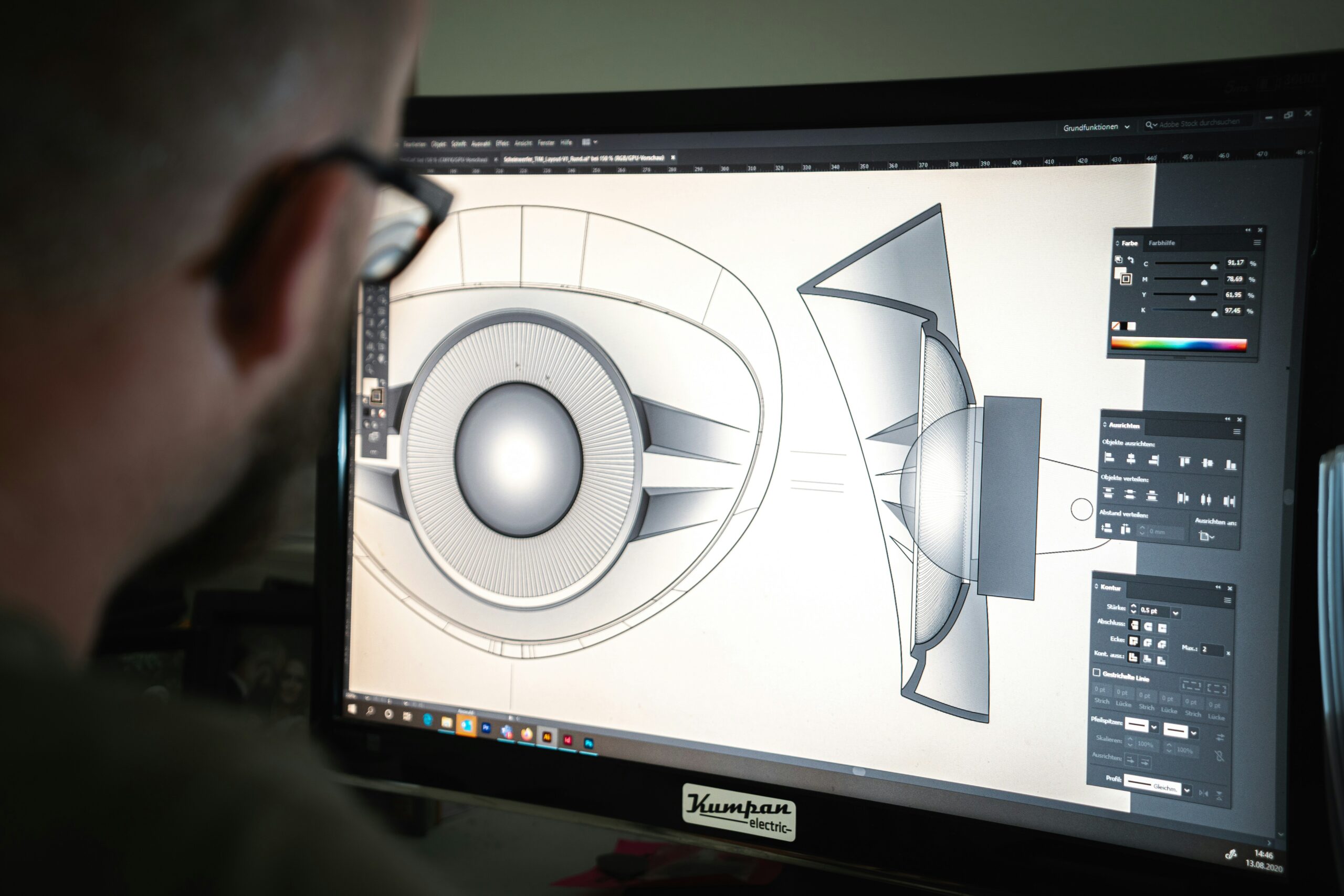

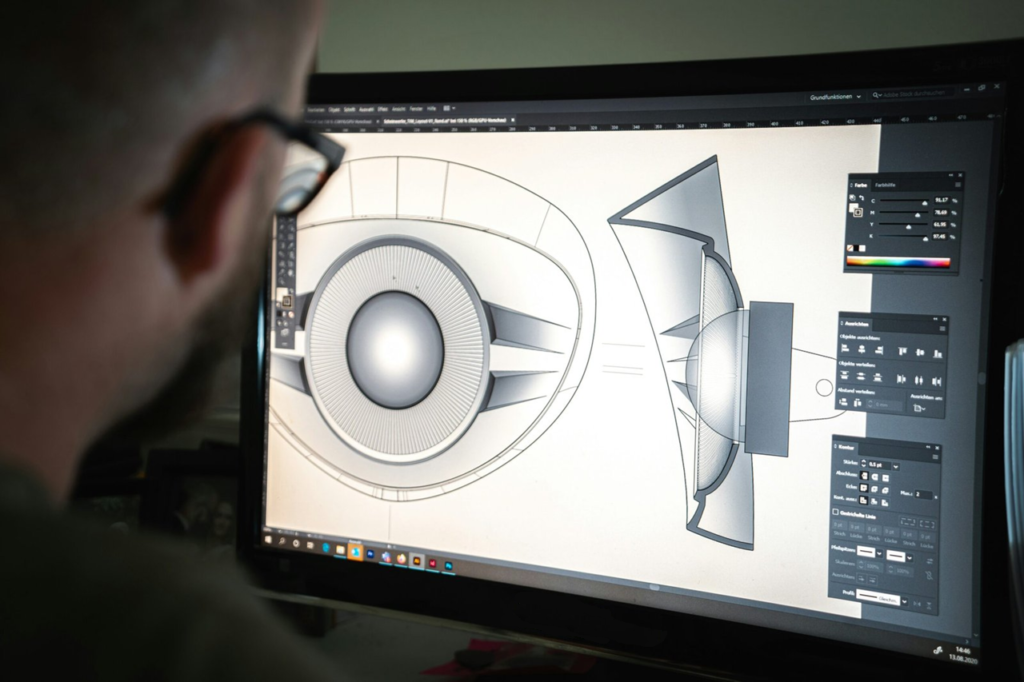

The product design journey begins with a thorough understanding of the client’s vision and market needs. Our team initiates this process through comprehensive brainstorming sessions that encourage collaboration. Here, we explore various ideas, methodologies, and potential technologies that align with the project objectives. This initial phase is crucial, as it serves as a foundation for the design. We utilize proven techniques that allow us to combine creativity with strategic thinking, ensuring that each concept is viable and innovative.

Once the concepts are refined, we transition into the development of prototypes. This step is pivotal in the product design process, as it allows us to translate ideas into tangible models. Prototyping provides an opportunity for our clients to see their vision come to life, facilitating early detection of any issues that may arise. During this stage, our designers actively seek feedback, which serves as a critical component of our iterative design approach. By continuously refining the product based on real user insights, we ensure that the end result aligns perfectly with the market demands.

Collaboration remains a core aspect throughout each phase of design. We work closely with our clients, engaging them in every step—from initial brainstorming through to prototype creation and final iterations. This partnership not only enhances the creative process but also fosters transparency and trust. Our designers remain accessible and responsive, enabling open lines of communication. Ultimately, our goal is to deliver a product that is not only functional but also resonates with the target audience, effectively bridging the gap between concept and reality.

Advanced Manufacturing Solutions

In today’s rapidly evolving manufacturing landscape, advanced manufacturing solutions play a pivotal role in enhancing productivity and driving innovation. One standout technology is 3D printing, particularly its application in the creation of manufacturing aids and production tools. This additive manufacturing process not only simplifies complex geometries but also provides a level of customization that traditional methods often struggle to achieve.

Employing 3D printing for manufacturing aids can significantly reduce both costs and material waste. Conventional manufacturing techniques often necessitate expensive molds and tooling, which can be time-consuming and resource-intensive. In contrast, 3D printing allows for the rapid prototyping of these aids. This means that design iterations can occur at an accelerated pace, enabling manufacturers to respond promptly to market demands without incurring heavy initial costs.

Another notable advantage of utilizing 3D printed tools is the reduction in weight, which results in enhanced efficiency of assembly lines. Lighter manufacturing aids can lead to improved ergonomics, thereby facilitating easier handling and reduced fatigue for workers. Additionally, by streamlining the assembly process, manufacturers can increase their throughput, thereby maximizing overall operational efficiency.

At our additive manufacturing center for metal, we harness the capabilities of advanced 3D printing technologies to produce high-quality parts and tools with remarkable precision. This facility allows us to utilize sophisticated metal additive manufacturing techniques that can withstand high-stress environments. The benefits extend beyond just manufacturing aids; they also include the ability to create complex components that traditional machining methods may find challenging.

Ultimately, the integration of advanced manufacturing solutions such as 3D printing into production processes not only streamlines operations but also fosters a culture of innovation. By reducing costs, enhancing design flexibility, and improving assembly line efficiency, these solutions represent a significant leap forward in the realm of modern manufacturing.

Expert Advice and Support for Startups and Inventors

In today’s fast-paced technological landscape, startups and inventors often face unique challenges that require specialized support. Comprehensive product design services provide the expert advice and guidance necessary during the critical stages of product development. From ideation to execution, these services facilitate the transformation of initial concepts into viable market-ready products. Our team offers tailored strategies that address the specific needs of entrepreneurs, ensuring that their innovative ideas are articulated clearly and positioned competitively.

One of the key advantages of engaging with our product design services is the depth of knowledge we offer in software solutions. Startups frequently need to navigate complex software environments to bring their products to life, and our expertise helps simplify this process. By leveraging cutting-edge technologies and best practices, we ensure that inventors can connect their hardware designs seamlessly with software applications, resulting in a cohesive and functional product. This not only enhances product usability but also significantly elevates the overall user experience.

Additionally, our comprehensive manufacturing support equips startups with the resources and understanding necessary for efficient production. We guide entrepreneurs through the intricacies of material selection, prototyping, and manufacturing processes, allowing them to make informed choices that align with their project goals. For instance, we collaborated with a budding inventor who sought to launch an eco-friendly gadget. By providing integrated support in design, material sourcing, and production planning, we helped them navigate the journey to a successful market launch, highlighting the effectiveness of our services.

Ultimately, our commitment to fostering innovation empowers startups and inventors to explore their creative potential with confidence. With our expert advice and comprehensive support, we strive to inspire entrepreneurs to overcome challenges and realize their visions, driving the next wave of technological advancements.